# Manufacturer Geotextile Purchase Guide: Tips for Buying Quality Geotextiles

When it comes to construction, civil engineering, or environmental projects, geotextiles play a crucial role in ensuring stability, drainage, and erosion control. However, purchasing the right geotextile from a reliable manufacturer can be a daunting task. This guide will walk you through the essential tips for buying quality geotextiles.

## Understanding Geotextiles

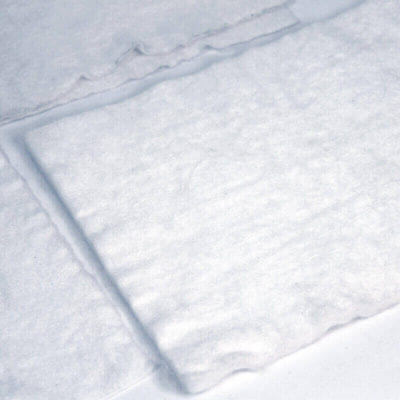

Geotextiles are permeable fabrics used in association with soil to enhance its properties. They are commonly made from synthetic materials like polyester or polypropylene and are available in woven, non-woven, and knitted forms. Each type serves specific purposes, such as filtration, separation, reinforcement, or drainage.

## Key Factors to Consider When Buying Geotextiles

### 1. Material Composition

The material of the geotextile determines its durability and performance. Polypropylene and polyester are the most common materials. Polypropylene is resistant to chemical degradation, while polyester offers higher tensile strength. Choose a material that aligns with your project requirements.

### 2. Type of Geotextile

– **Woven Geotextiles**: Ideal for applications requiring high tensile strength, such as road construction.

– **Non-Woven Geotextiles**: Best for filtration and drainage purposes, often used in landscaping and drainage systems.

– **Knitted Geotextiles**: Less common but useful for specialized applications requiring flexibility.

### 3. Weight and Thickness

The weight and thickness of the geotextile affect its performance. Heavier geotextiles are generally more durable and suitable for high-stress applications. However, lighter options may be sufficient for less demanding tasks.

### 4. Permeability

Permeability is crucial for drainage and filtration applications. Ensure the geotextile has the appropriate permeability rating to allow water to pass through while retaining soil particles.

### 5. UV Resistance

If the geotextile will be exposed to sunlight, UV resistance is essential to prevent degradation over time. Check the manufacturer’s specifications for UV resistance ratings.

### 6. Certification and Standards

Ensure the geotextile meets industry standards and certifications. Look for products that comply with ASTM, ISO, or other relevant standards to guarantee quality and performance.

## Choosing the Right Manufacturer

Selecting a reputable manufacturer is as important as choosing the right geotextile. Here are some tips:

– **Experience and Reputation**: Opt for manufacturers with a proven track record and positive customer reviews.

– **Customization Options**: Some projects may require custom geotextiles. Choose a manufacturer that offers customization to meet your specific needs.

– **Technical Support**: A good manufacturer should provide technical support and guidance to help you select the right product for your project.

– **Delivery and Logistics**: Consider the manufacturer’s ability to deliver on time and handle logistics efficiently.

## Conclusion

Buying quality geotextiles from a reliable manufacturer is essential for the success of your project. By considering factors like material composition, type, weight, permeability, UV resistance, and certifications, you can make an informed decision. Additionally, choosing a reputable manufacturer with experience, customization options, and excellent customer support will ensure you get the best product for your needs. Happy geotextile shopping!

Keyword: Manufacturer geotextile buy